7 Step DPF Cleaning Process

Excalibre have invested in high technology DPF cleaning and test equipment for diesel vehicles. We adhere to the same standards as all the major engine OEMs, including the use of the FSX cleaning centre, the cleaning process, testing, and reporting.

1.

Goods inwards – unique ID number added

2.

Initial flow test and visual inspection

3.

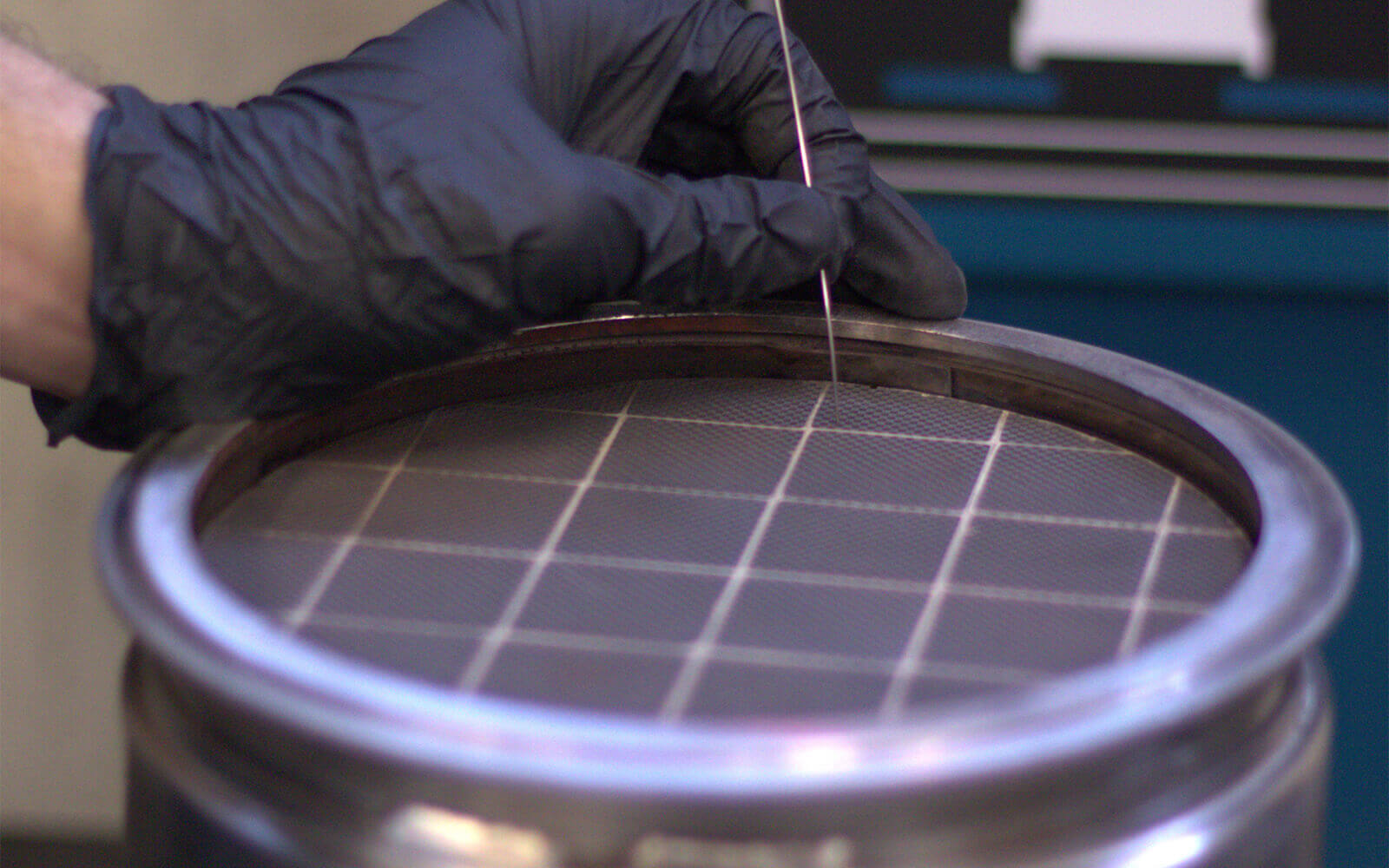

Pin test – checks for exothermed cells

4.

Breached cell test – detects exhaust bypass

5.

FSX Pneumtatic cleaning – removes all soot and ash

6.

Flow test – ensures baseline conditions met

→

Optional thermal treatment – to assist removal of compacted ash

7.

Inspection reports completed and unit despatched

FSX Cleaning System

The FSX cleaning system is state of the art and is used by the majority of engine OEM’s including Cummins, Volvo and DAF.

Importantly, as well as effectively cleaning the DPF the process also evaluates the condition and suitability for re-use and emissions compliance. Excalibre have an extensive database of baseline flow reading for the full range of DPF’s. After the cleaning process each DPF’s flow characteristics are checked against the database to ensure the flow is retuned to baseline. Where the parameters are not met the process is repeated together with an optional thermal process.